With the rapid development of 5G, artificial intelligence, and electric vehicles, electronic devices are evolving towards higher frequencies, higher efficiency, and more compact designs. In this wave, the core component of power supplies—the transformer—has also undergone a revolutionary evolution from wire-wound to printed circuits.

PCB transformers, with their inherent advantages, have become the preferred choice for high-end power supply designs. However, the performance of products on the market varies greatly, and behind superior performance lies a profound technological gap.

Let's take some examples of the challenges electronic device design engineers encounter when designing power modules.

Engineers typically need to overcome several conflicting key challenges:

- Size Constraints: As devices become increasingly smaller, power modules must also be very compact, directly limiting the space layout of internal componentsEfficiency Requirements: Power conversion cannot waste too much energy. High efficiency means longer battery life and less heat generation, but achieving high efficiency often requires more complex circuit designs.

- Heat Dissipation Challenges: Heat generated in small spaces is difficult to dissipate. Overheating can 2_affect power supply performance, shorten component lifespan, and even cause safety issues.

- Consistency Guarantee: Every power module in mass production must have stable and reliable performance, without fluctuations due to temperature variations or component differences.

These challenges become even more complex when using PCB transformers:

- While PCB transformers can be made thinner and smaller, helping to reduce overall size.

- They also introduce new problems: copper foil windings are prone to overheating, current carrying capacity is limited, and losses increase at high frequencies.

- These characteristics directly affect the power supply's efficiency and heat dissipation difficulty.

- Furthermore, it is necessary to ensure the manufacturing precision of each PCB transformer; otherwise, the consistency of the entire batch of products will be affected.

Therefore, engineers must find the best balance among these mutually restrictive factors: small size, high efficiency, good heat dissipation, and stable performance. This is like walking a tightrope, requiring careful design and repeated optimization.

Hongrong (Shenzhen) Electronics Co., Ltd. has been deeply involved in the PCB transformer field for many years, and we understand that "excellence" is not just a marketing slogan, but stems from the relentless pursuit of perfection in every technical detail.

Today, we will frankly tell you from five dimensions why our PCB transformers can truly achieve superior performance.

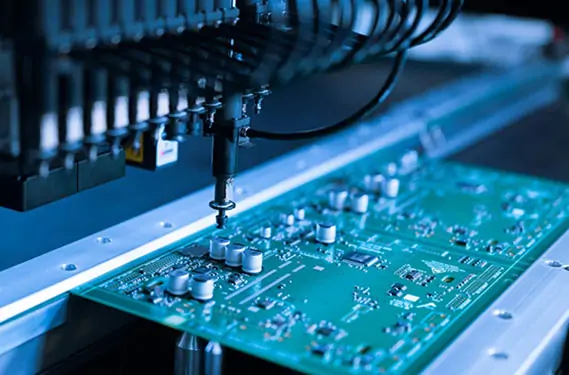

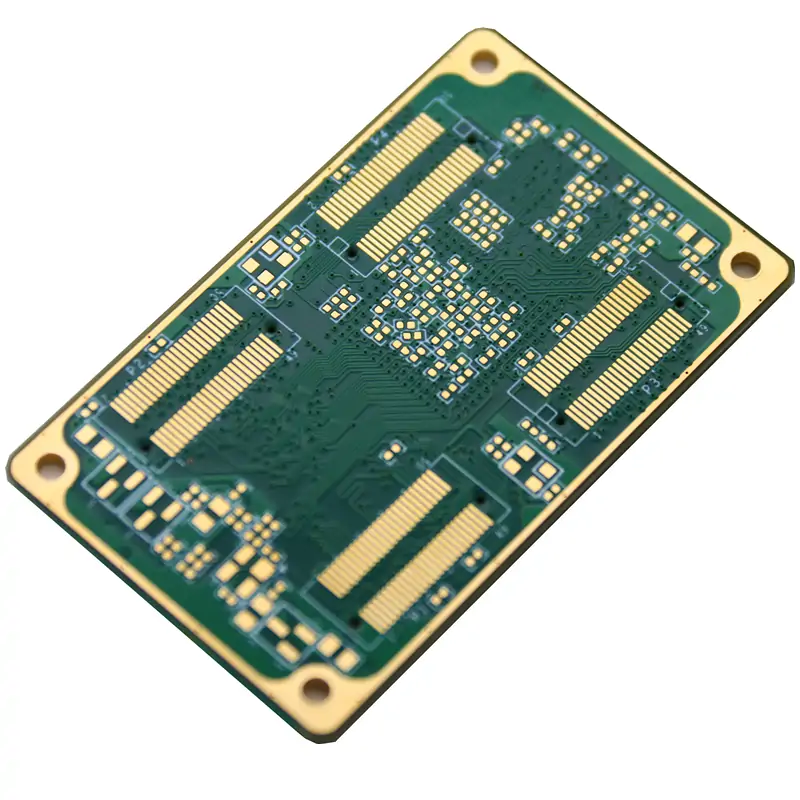

I. Precision Manufacturing Process, Ensuring Millimeter-Level Accuracy and Consistency

- Automated Etching Technology: Utilizing high-precision laser direct imaging (LDI) technology to ensure winding accuracy of ±10 micrometers.

- Fully Automated Process: From winding formation to soldering and packaging, the entire process is automated, eliminating human error.

- Multi-Layer Alignment Control: Precise stacking of 8-12 layer PCBs, with inter-layer deviation <0.02mm.

- Results: Batch-level inductance dispersion <3%, exceeding the industry average by 50%.

II. High-Frequency, Low-Loss Design for Breakthrough Energy Efficiency

- Structural Advantages: Planar windings inherently possess low leakage inductance, reducing leakage inductance by over 40%.

- High-Frequency Adaptation: Optimized parasitic parameters maintain efficiency of 92%+ at 1MHz.

- EMI Suppression: Integrated shielding layer and balanced winding structure reduce conducted interference by 12dB.

- Practical Benefits: Customer-tested overall efficiency improvement of 0.5-1.2% and temperature rise reduction of 10-15℃.

III. Intelligent Thermal Management for Continuous and Stable Operation

- Three-Dimensional Heat Dissipation Channels:Vertical Direction:

1) Dense array of thermally conductive holes, reducing thermal resistance by 60%

2) Plane Direction: Embedded copper layer for uniform heat dissipation, hot spot temperature difference <10℃

- Material Innovation: Utilizes a high thermal conductivity substrate (1.8W/mK) to improve heat diffusion efficiency

- Reliability Verification: Passes 1000 thermal cycle tests from -40℃ to 125℃ without performance degradation.

IV. Deep Customization Capabilities, Precisely Matching Application Needs

- Rapid Response: Parametric design platform, providing customized solutions within 5 working days

- Flexible Integration: Supports composite designs such as multi-winding, center taps, and integrated filter circuits

- Scenario Optimization:

1) New Energy Vehicle Power Supply: Enhanced vibration and high-temperature resistance

2) 5G Communication: Optimized high-frequency response and EMC characteristics

3) Industrial Power Supply: Emphasis on high power density and long-term reliability

V. End-to-End Quality Control, Building a Zero-Defect System

- Strict Material Selection: Graded management of FR4/Rogers/metal substrates, incoming material inspection pass rate >99.8%

- Process Monitoring: 37 key quality control points, real-time data acquisition and analysis

- Rigorous Testing:

1) 100% electrical performance testing (withstand voltage, insulation, turns ratio)

2) Fully automated flying probe testing, 100% defect detection rate

3) Batch sampling HALT limit life testing

- Traceability System: Each product has a unique code, and all production data is traceable

Hongrong Electronics redefines the performance benchmark for PCB transformers through a five-dimensional synergy of

"precision manufacturing + high-frequency design + intelligent heat dissipation + deep customization + full-chain quality control." We not only provide components, but also offer customers quantifiable, verifiable, and replicable performance advantages, helping your products achieve comprehensive leadership in efficiency, size, and reliability.

PCB transformers are widely used in the power supply and signal isolation fields of modern electronic equipment due to their significant advantages of high frequency, high efficiency, small size and good consistency.

Key application industries include:

- Communications and Networks: Power supplies for 5G base stations, data center servers, optical modules, and other equipment, requiring high-frequency, low-loss characteristics.

- New Energy Vehicles: On-board chargers (OBCs) and DC-DC converters, with high power density and high reliability as core requirements.

- Industry and Power Supply: Power supplies for industrial control equipment, servo drives, and testing instruments, emphasizing stable heat dissipation and long-term durability.

- High-End Consumer Electronics: GaN fast chargers and thin and light adapters, pursuing extreme miniaturization and high efficiency.

- Medical Devices: Imaging equipment and patient monitors, requiring strict safety isolation standards.

Furthermore, in aerospace, IoT, and military industries with stringent performance requirements, PCB transformers are also the preferred choice due to their excellent consistency and environmental adaptability.

High-performance PCB transformers require specialized soldering techniques to fully unleash their potential. Improper soldering increases resistance, impairs heat dissipation, and can even damage internal precision structures, leading to performance degradation.

Therefore, high-quality components are fundamental, but perfect soldering is key. For guidance on how to solder transformers to achieve 100% performance, please refer to our guide: "

How to Solder a PCB Circuit Board Without Errors?" covering everything from pad design to post-soldering inspection to ensure superior performance throughout.

Conclusion

The unparalleled performance of our PCB transformers stems from the systematic integration of five core advantages: micron-level precision and ultra-low dispersion achieved through meticulous manufacturing; energy efficiency breakthroughs achieved through high-frequency optimized design; stable operation ensured by a three-dimensional heat dissipation architecture; precise matching of scenario requirements through deep customization capabilities; and zero-defect delivery guaranteed by a comprehensive quality control system. This is not merely about leading technical parameters, but a commitment to reliability throughout the entire process from design to mass production—we deliver not just components, but proven power density, efficiency, and consistency advantages, helping your products surpass competitors in size, performance, and reliability. Choosing us means choosing quantifiable, replicable, and customizable performance assurance.

Hongrong (Shenzhen) Electronics Co., Ltd. provides one-stop electronic manufacturing services, focusing on high-quality PCB manufacturing and assembly, covering the entire process from production to testing. We also offer professional component procurement, leveraging a global supply chain to ensure genuine product supply and cost optimization, helping customers launch their products quickly.