High-frequency applications are widely deployed in high-speed communication systems, radar detection, satellite navigation, RFID devices, automotive millimeter-wave modules, microwave power amplification, and high-frequency power conversion equipment. These systems operate from several hundred megahertz to tens of gigahertz. Signal integrity at high frequencies is a fundamental determinant of system performance.

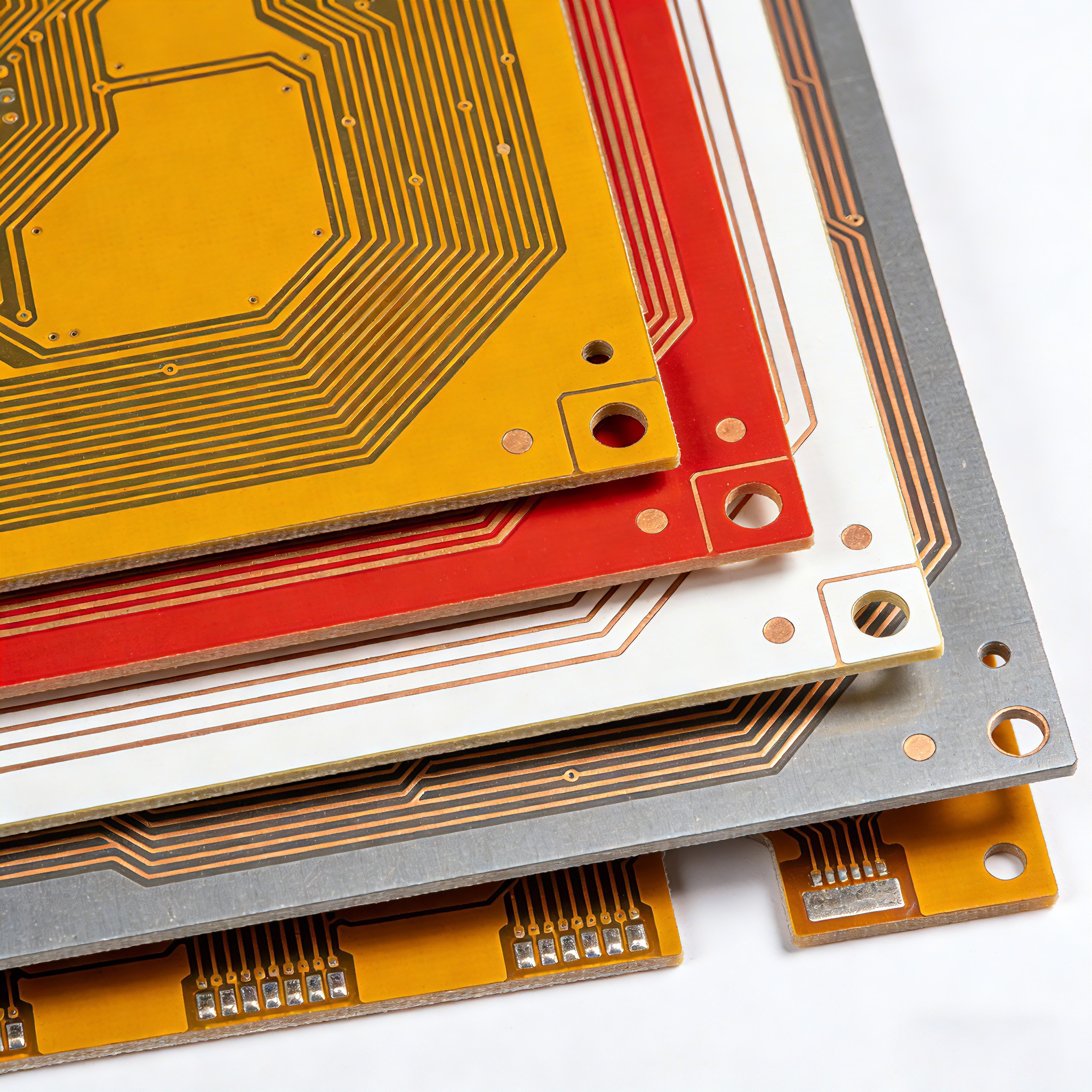

In hih-frequency conditions, the printed circuit board does not merely provide mechanical support and electrical interconnection. The PCB substrate must facilitate low-loss transmission and maintain stable impedance. Electromagnetic wave propagation within the dielectric is strongly affected by the dielectric constant, dielectric loss, thermal conductivity, coefficient of thermal expansion, and other material parameters. Insufficient performance can result in increasing transmission loss, phase distortion, parasitic effects, and electromagnetic interference, which degrade long-term system reliability. For this reason, high-frequency applications impose special material requirements on PCB substrates.

Selecting the best PCB material for high-frequency applications therefore becomes a critical aspect of high-frequency circuit design. The choice among FR-4, PTFE, Rogers materials, and other RF PCB substrates influences dielectric performance, EMI ehavior, manufacturability, cost, and signal loss. This article analyzes high-frequency PCB material properties, compares commonly used high-frequency PCB substrates, and presents guidance for material selection to support RF, microwave, and millimeter-wave system performance.

In the previous article on PCB transformer design, transmission efficiency was shown to depend on conductor losses, magnetic losses, and dielectric losses. The dielectric properties of the PCB substrate significantly affect insulation capability and high-frequency energy transfer. Therefore, the discussion of high-frequency PCB materials in this article extends the technical considerations introduced in the PCB transformer context, emphasizing the importance of substrate selection for achieving higher efficiency and lower losses in high-frequency systems.

The selection of PCB substrate materials is critical in high-frequency applications due to the following factors:

| PCB Substrate Type | Dielectric Constant Dk (Typical) |

Dielectric Loss Df (Typical) |

High-Frequency Performance | Manufacturability | Cost Level | Typical Applications |

| Standard FR-4 | 4.2 – 4.8 | 0.015 – 0.025 | Poor for >1 GHz | Mature and easy to fabricate | Low | Consumer electronics, low-speed digital |

| Low-loss FR-4 | 3.6 – 4.2 | 0.008 – 0.015 | Moderate performance | Mature process | Medium-Low | Broadband, mid-speed signal routing |

| PTFE | 2.1 – 2.35 | 0.0002 – 0.002 | Excellent RF/microwave performance | Difficult to process | High | RF, microwave, radar, mmWave |

| Ceramic-filled PTFE | 2.4 – 3.5 | 0.0003 – 0.004 | Excellent, high stability | Medium processing difficulty | High | Power amplifiers, mmWave antennas |

| Rogers laminates (RO4350/4003 etc.) | 3.0 – 3.66 | 0.002 – 0.004 | Outstanding RF performance | Easier to fabricate than PTFE | Medium-High | 5G RF front-end, filters, high-frequency PCB |

| Polyimide | 3.2 – 4.0 | 0.004 – 0.01 | Moderate, good thermal stability | Good manufacturability | Medium-High | Aerospace, high-temperature HF circuits |

| Metal-core / ceramic substrates | 6.0+ (varies significantly) | Very low | Excellent thermal and HF behavior | Complex processing | High | Automotive mmWave radar, high-power modules |

| PCB Material | High-Frequency Signal Loss | Impedance Stability | EMI Suppression Capability | Thermal Reliability | Manufacturability | Cost Suitability | Typical Frequency Range |

| FR-4 | High loss; not recommended for RF/high-frequency | Poor | Weak | Moderate | Excellent | Excellent (low cost) | < 1 GHz |

| Low-loss FR-4 | Lower loss; suitable for moderate HF | Fair | Fair | Moderate | Excellent | Medium-low | 1–3 GHz |

| PTFE | Very low loss with high signal fidelity | Excellent | Excellent | High | Poor (complex processing) | High cost | 1–40+ GHz |

| Ceramic-filled PTFE | Low loss with enhanced stability | Excellent | Excellent | Very high | Medium processing difficulty | High cost | 10–100+ GHz |

| Rogers laminates (RO4350/4003, etc.) | Low loss and competitive performance | Good | Good | Medium-high | Good | Medium-high | 3–40+ GHz |

| Polyimide | Moderate loss | Fair | Moderate | Excellent (high-temperature stability) | Good | Medium-high | 1–10 GHz |

| Metal-core / ceramic substrates | Extremely low loss | Excellent | Excellent | Very high | Complex processing | High | 10–100+ GHz, high-power systems |

| Material Type | Key Characteristics | High-Frequency Performance | Typical Applications |

| PTFE (Polytetrafluoroethylene) | Low dielectric constant, very low loss, strong chemical stability, difficult to process | Excellent, suitable for UHF and millimeter-wave applications | Microwave circuits, radar, satellite communication |

| High-frequency composites (ceramic-filled/resin blend) | Stable dielectric properties, low thermal expansion, strong mechanical strength, good PCB compatibility | Excellent, low transmission loss and dimensional stability | 5G base stations, PA amplifiers, high-speed interconnects |

| PPO/PP (Polyphenylene oxide / Polypropylene) | High material uniformity, low loss, high manufacturability | Good, suitable for RF and high-frequency signal routing | High-frequency servers, communication antenna modules |

| Modified epoxy/phenolic systems | Good manufacturability, moderate cost, slightly higher dielectric loss | Medium, suitable for mid-frequency RF designs | Mid-band RF modules, consumer RF electronics |

| Low-loss FR-4 (high-Tg grades) | Low cost, widely available, higher loss and unstable dielectric at high frequencies | Fair, limited suitability for high-frequency systems | Low-cost Wi-Fi / IoT RF boards |

| Ceramic substrates | Excellent thermal performance, very low loss, high cost, demanding processing | Excellent, suitable for extreme-frequency and high-power systems | RF power modules, aerospace / defense electronics |

High-frequency PCB substrates are engineered to support electronic systems operating at high frequency, high speed, or microwave ranges. Material selection affects signal attenuation, dielectric stability, impedance control, and overall reliability. The following summarizes mainstream application fields where high-frequency PCB materials are required.

1. Communication Systems

High-frequency materials are widely deployed in modern wireless, broadband, and RF networking devices. Typical structures include:

In these systems, minimizing loss and dispersion is critical. Stable dielectric properties enable controlled impedance and maintain consistent transmission performance across operating bandwidths.

2. Satellite and Aerospace Systems

High-frequency PCB materials support microwave and millimeter-wave communication links in aerospace environments. Common use cases include:

Controlled thermal expansion, dielectric consistency, and mechanical stability are essential due to extreme temperature cycling and environmental constraints.

3. Radar and Sensing Systems

High-frequency substrates are incorporated into radar platforms and precision sensing devices. Application structures include:

Low-loss materials suppress parasitic effects and improve propagation velocity consistency to ensure high-resolution signal acquisition and processing.

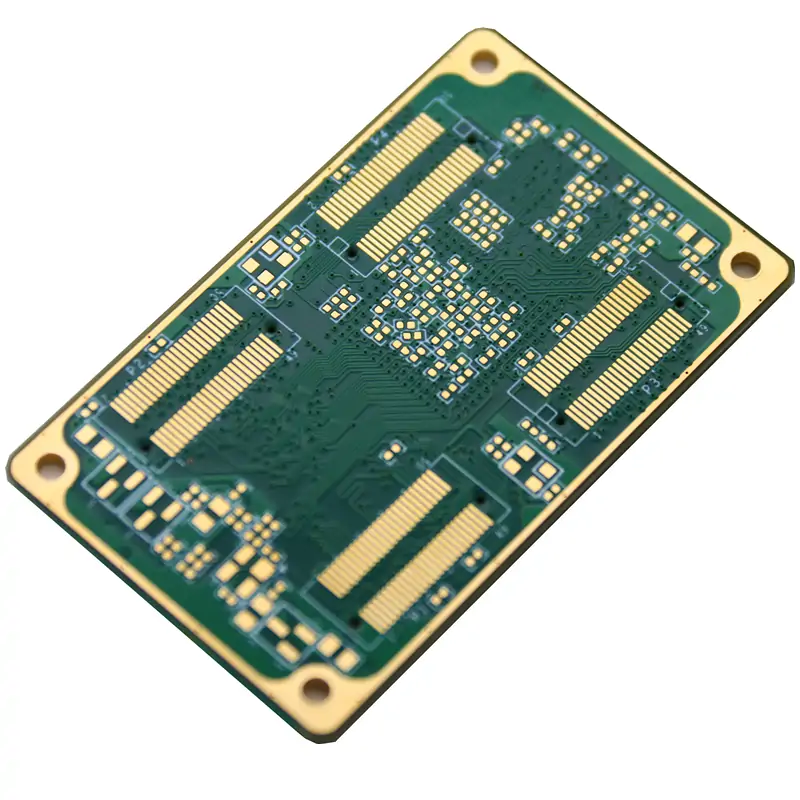

4. High-Speed Computing and Interconnect Systems

Computing platforms require substrates capable of maintaining signal integrity at very high data rates. Representative applications include:

Substrate selection directly influences jitter, crosstalk, insertion loss, and eye-diagram stability.

5. Industrial and Test Instrumentation

High-frequency PCB materials enable precision in industrial control and measurement equipment. Applications include:

Stable dielectric properties improve measurement repeatability and consistency across operating frequencies.

High-frequency PCB applications require substrate materials with stable dielectric properties, controlled loss characteristics, and reliable structural performance. This article analyzed mainstream high-frequency PCB materials, key selection parameters, application classifications, comparative performance tables, and decision criteria. These discussions demonstrate that material characteristics directly influence signal integrity, transmission efficiency, power handling capability, and overall system stability. The content builds on the prior article regarding PCB transformers, emphasizing the relationship between materials, electrical performance, and manufacturability in high-frequency environments.

Across communication systems, satellite and aerospace platforms, radar and sensing equipment, industrial instrumentation, and high-speed computing, material specifications and manufacturing feasibility determine design success. Engineering teams should evaluate dielectric constant, dissipation factor, thermal expansion, processing compatibility, and cost considerations when selecting high-frequency PCB substrates. The comparative tables, application summaries, and selection strategies provided in this article can support structured decision-making, reduce development risk, and improve long-term reliability.

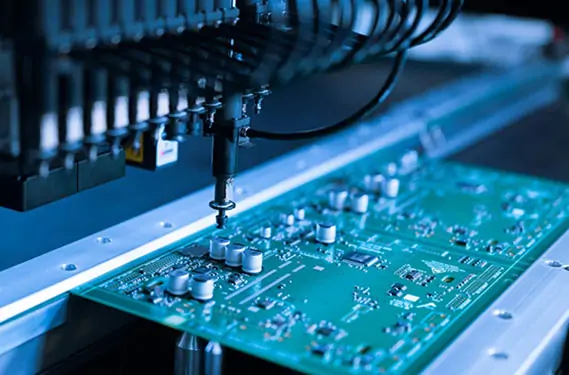

Reliable high-frequency PCB implementation also depends on manufacturing capability. Hongrong (Shenzhen) Electronics Co., Ltd. has twenty years of experience in PCB fabrication and assembly and provides one-stop services for high-frequency, high-speed, and multilayer PCB production. The company also supports material selection, process evaluation, and quality control consultation, enabling alignment between design intent and manufacturable performance.

Selecting appropriate high-frequency PCB materials is a critical process in the development of high-frequency and high-speed electronic systems. Organizations should integrate material characteristics, application requirements, and manufacturing capability into a unified evaluation framework to achieve stable transmission performance, improve system reliability, and support long-term operational quality.

Please contact us to experience the difference with high quality of HongRong (shenzhen) Electronics Co.,Ltd.