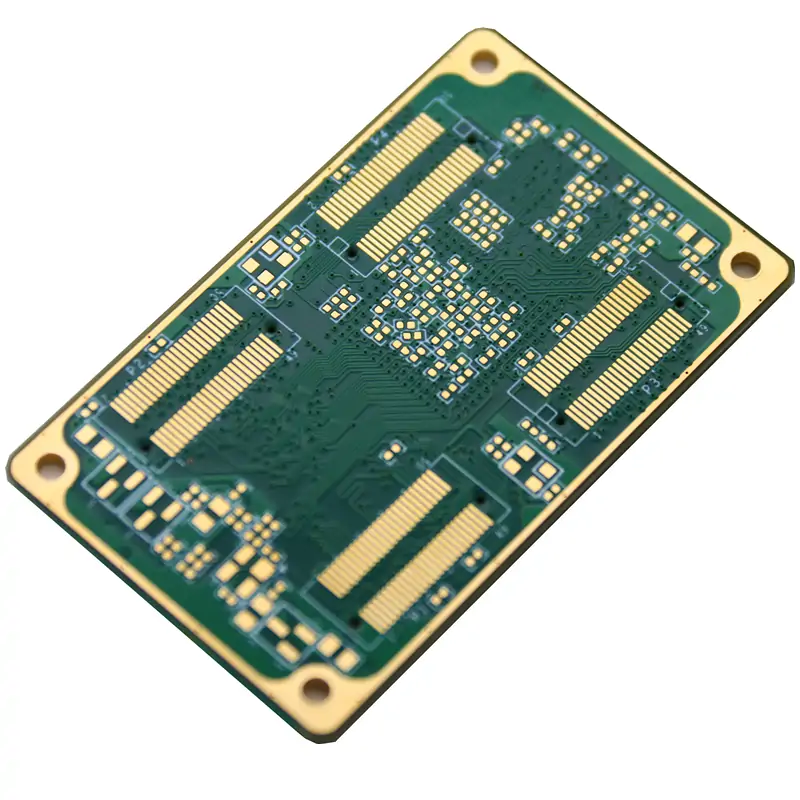

In printed circuit board design, engineers meticulously plan circuit layouts, select materials, and configure layer stack-ups. However, one critical protective layer is often overlooked—the PCB solder mask. This thin polymer coating is far more than decorative; it is a fundamental barrier that determines soldering success, electrical integrity, and long-term reliability.

At HongRong(shenzhen) Electronics Co.,Ltd., we understand that a high-quality solder mask is not merely applied—it is engineered. Through advanced materials science and precision manufacturing processes, we transform this essential layerinto a reliable shield for your most demanding applications.What Is a PCB Solder Mask? More Than Meets the Eye

A PCB solder mask is a permanent, lacquer-like polymer layer applied over the copper traces of a circuit board. Its primary function is to prevent accidental solder bridging during assembly by exposing only the metal pads intended for soldering.

However, its roles extend much further:

Insulation Layer: Acts as a dielectric barrier between adjacent conductive traces, which is especially critical in high-density designs.

Environmental Shield: Protects exposed copper from oxidation, moisture, chemical contaminants, and fungal growth.

Mechanical Protector: Guards against scratches, abrasion, and handling damage during assembly and throughout the product's lifecycle.

Aesthetic & Legend Base: Provides the board's characteristic color and serves as the surface for silkscreen markings.

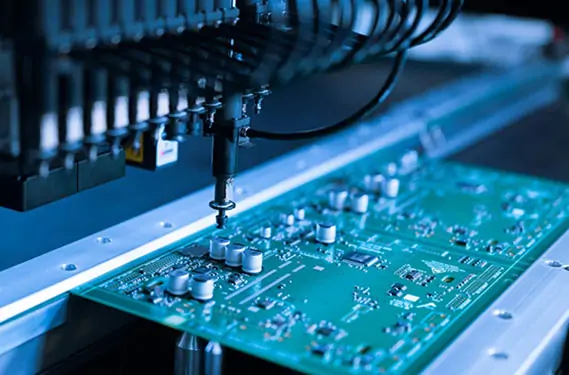

During Surface Mount Technology (SMT) reflow soldering or wave soldering, molten solder can behave unpredictably. A precisely applied solder mask with clean, sharply defined openings acts as a physical dam. It confines solder paste and molten solder strictly to the designated pads, significantly reducing the risk of shorts, solder balls, and bridging—especially on fine-pitch components and high-density ball grid arrays.

Electronic devices face relentless environmental stress:

Moisture & Humidity: Primary causes of electrochemical migration and copper oxidation.

Chemical Exposure: From flux residues to atmospheric pollutants.

Thermal Cycling: Repeated expansion and contraction that stresses materials.

Hongrong's solder mask formulations are selected and tested to create a hermetic, non-porous barrier. This prevents corrosive agents from reaching the copper, significantly enhancing the board’s Mean Time Between Failures (MTBF) and suitability for automotive, industrial, and outdoor applications.

As signal speeds increase and voltage clearances shrink, the electrical properties of every material become critical. Poor-quality solder mask can absorb moisture, leading to increased leakage current, reduced Surface Insulation Resistance (SIR), and signal degradation at high frequencies.

Our solder masks maintain stable dielectric properties across a wide range of temperatures and humidity. This ensures consistent impedance control and prevents parasitic currents that can disrupt sensitive analog or high-speed digital circuits.

From automated handling in pick-and-place machines to end-user wear and tear, PCBs endure physical stress. Our solder mask provides a tough, abrasion-resistant surface that protects fine traces from scratches that could break connections or reduce current-carrying capacity. This durability is paramount for connector edges, flex-rigid interfaces, and frequently handled assemblies.

Our commitment to solder mask excellence is built on three pillars:

We partner with leading global chemical suppliers to utilize solder mask inks known for:

High Thermal Reliability: Withstanding multiple lead-free reflow cycles without blistering or discoloration.

Excellent Adhesion: Strong bonding to various substrates to prevent delamination.

Halogen-Free & RoHS/REACH Compliance: Meeting the strictest global environmental and safety standards.

Technology is meaningless without precise execution. Our state-of-the-art manufacturing ensures quality:

LDI Technology: Enables ultra-precise solder mask dam definition between micro-spaced pads.

Uniform Coating & Controlled Thickness: Achieved through advanced coating systems.

Complete Process Integration: Optimized in tandem with surface finishes for perfect compatibility.

Every batch undergoes stringent inspection:

Automated Optical Inspection (AOI): Scans for pinholes, voids, and registration errors.

Adhesion Cross-Hatch Test: Verifies bond strength.

Thermal Shock & Humidity Testing: Validates performance under accelerated aging.

To clearly demonstrate Hongrong's advantages, the table below compares key performance metrics across solder mask grades:

| Performance Metric | Hongrong Standard Grade | Hongrong High-Performance Grade | Industry Basic Grade | Implication for Your Design |

|---|---|---|---|---|

| Heat Resistance (T288) | ≥ 5 cycles | ≥ 10 cycles | 2-3 cycles | Supports multiple reworks & complex assembly |

| Insulation Resistance | > 10⁸ MΩ | > 10¹⁰ MΩ | 10⁶ - 10⁷ MΩ | Ensures stability in high-impedance circuits, reduces leakage |

| Dielectric Constant (Dk) @1MHz | 3.2 ± 0.2 | 3.0 ± 0.1 | 3.5 - 4.0 | Better signal integrity, especially for high-frequency apps |

| Min. Solder Mask Dam Width | 0.075 mm | 0.050 mm | 0.100 mm | Enables higher-density ICs & fine-pitch designs |

| Adhesion (Cross-Cut) | 5B (Best) | 5B (Best) | 3B - 4B | Prevents delamination under thermal/mechanical stress |

| Chemical Resistance | Excellent | Superior | Average | Resists corrosion from flux, cleaners, etc. |

1. Does solder mask color affect performance?

While the base resin determines performance, darker pigments can absorb more heat during reflow. For complex, dense boards, green or blue are often recommended. Hongrong can advise on the best choice for your application.

2. How is solder mask applied for ultra-fine-pitch components?

For HDI boards, we employ LDI technology and Liquid Photoimageable (LPI) solder masks, creating precise dams as narrow as 2 mils (0.05mm).

3. What about solder mask for high-voltage or high-frequency boards?

For high-voltage applications, we ensure uniform, void-free coating. For RF/microwave boards, we select masks with low, stable Dk and Df values to minimize signal loss.

4. How does Hongrong support prototyping with solder mask requirements?

Even for prototypes, we apply the full-process solder mask—not just legend ink—ensuring performance matches final production.

The solder mask is the unsung hero of PCB reliability. Choosing a partner who masters this critical element is a strategic decision for product quality.

With decades of expertise, HongRong(shenzhen) Electronics Co.,Ltd. delivers engineered protection. From consumer electronics to mission-critical automotive and medical devices, our solder mask solutions ensure your boards perform flawlessly, today and for years to come.

Ready to build more reliable electronics? Contact our engineering team today to discuss how our advanced PCB manufacturing and solder mask solutions can protect your next design.

Please contact us to experience the difference with high quality of HongRong (shenzhen) Electronics Co.,Ltd.