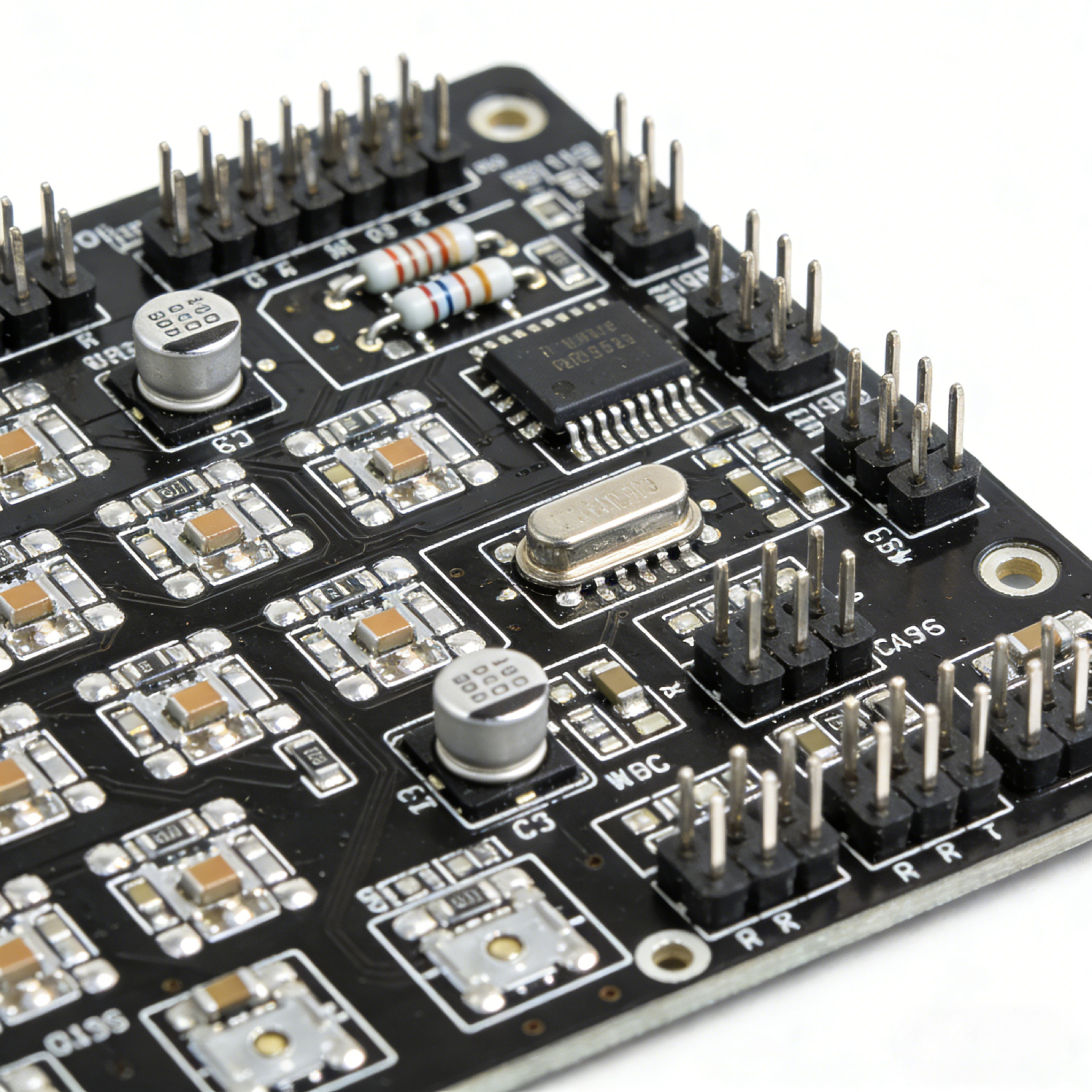

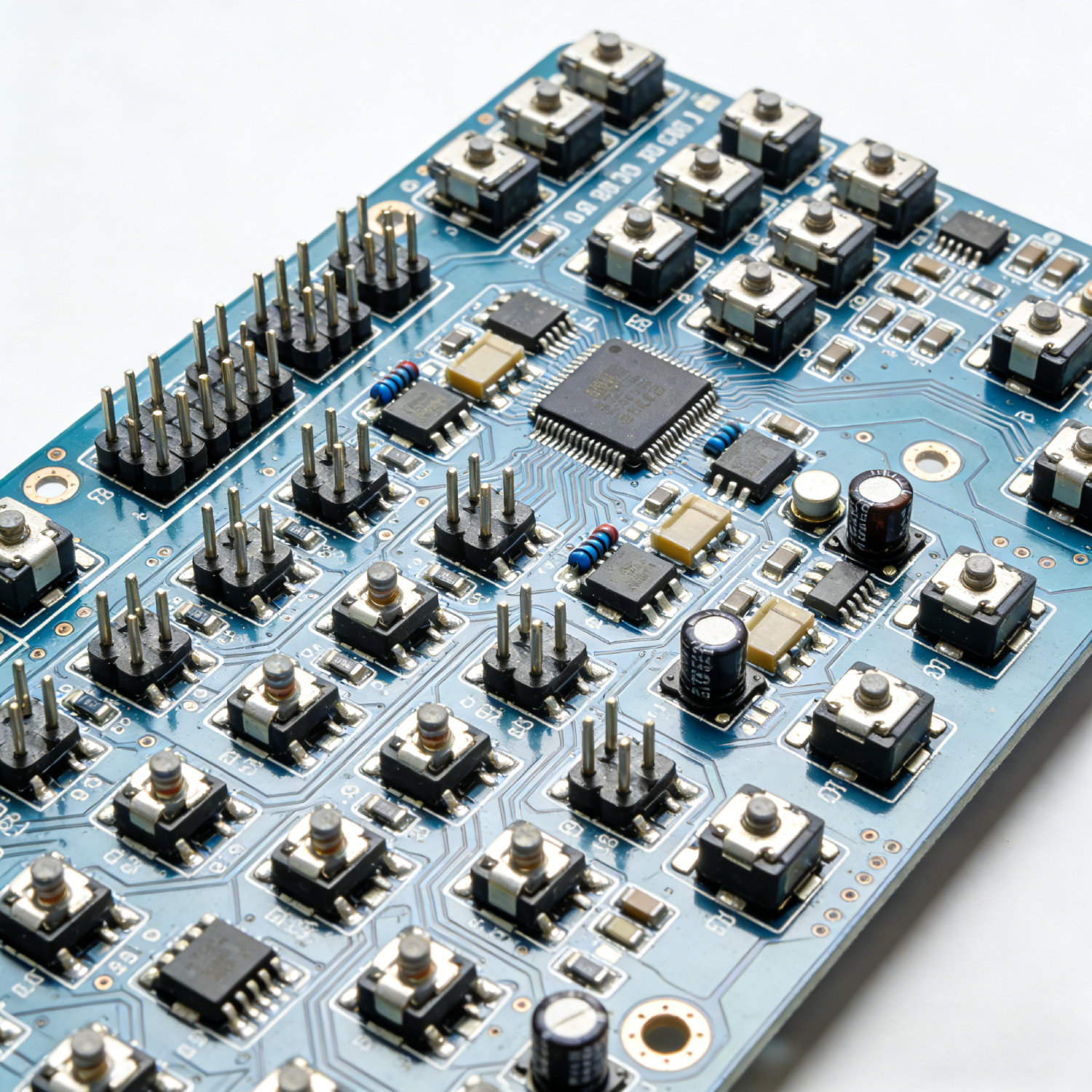

Custom mechanical keyboards have rapidly transitioned from enthusiast-driven DIY projects to commercially scalable products. At the core of every keyboard is the PCB, which determines electrical reliability, signal integrity, and long-term durability.

For brands, keyboard designers, and hardware startups, understanding how to design a manufacturing-ready custom keyboard PCB is critical. As a professional PCB manufacturer and PCBA service provider, HongRong (Shenzhen) Electronics Co., Ltd. supports customers throughout the entire process—from design optimization to mass production and assembly.

This guide explains how to make a custom keyboard PCB step by step, with a strong focus on B2B manufacturing, cost control, and production efficiency.

A custom keyboard PCB is a purpose-designed printed circuit board that defines the keyboard’s layout, electrical connections, and functional expandability. Compared with standard off-the-shelf PCBs, custom designs allow brands to:

Control key layout and matrix structure

Select appropriate MCUs for long-term supply

Support hot-swap or soldered switches

Integrate RGB, rotary encoders, OLED displays, or wireless modules

From a manufacturing perspective, a well-designed custom keyboard PCB directly improves yield rate, assembly consistency, and delivery stability—key factors for commercial keyboard projects.

Before schematic design, clearly define:

Keyboard form factor (60%, 65%, 75%, TKL, full-size)

Target market (DIY kits or fully assembled keyboards)

Hot-swap or soldered switch solution

USB interface type (commonly USB Type-C)

At HongRong, early-stage requirement review helps customers reduce unnecessary design revisions and shorten PCB fabrication lead time.

Select the Right MCU

MCU selection impacts both functionality and supply chain stability. For B2B projects, considerations include:

Sufficient GPIO pins for key matrix scanning

USB compatibility and firmware support

Availability and long-term sourcing reliability

Using widely adopted MCUs simplifies PCBA and reduces procurement risks.

A production-oriented schematic includes:

Switch and diode connections

MCU pin mapping

USB interface, power regulation, and ESD protection

Clear schematics reduce misinterpretation during PCB fabrication and PCBA.

Most keyboard PCBs use 2-layer FR-4 boards. Manufacturing-friendly routing includes:

Short, direct signal paths

Continuous ground reference

Uniform trace width and spacing

At HongRong, designs are reviewed against DFM rules to ensure smooth mass production.

Typical deliverables include:

Gerber files

Drill files

Pick-and-place files (for PCBA)

Pre-production checks significantly reduce rework costs.

A production-oriented schematic includes:

Switch and diode connections

MCU pin mapping

USB interface, power regulation, and ESD protection

Clear schematics reduce misinterpretation during PCB fabrication and PCBA.

Typical deliverables include:

Gerber files

Drill files

Pick-and-place files (for PCBA)

Pre-production checks significantly reduce rework costs.

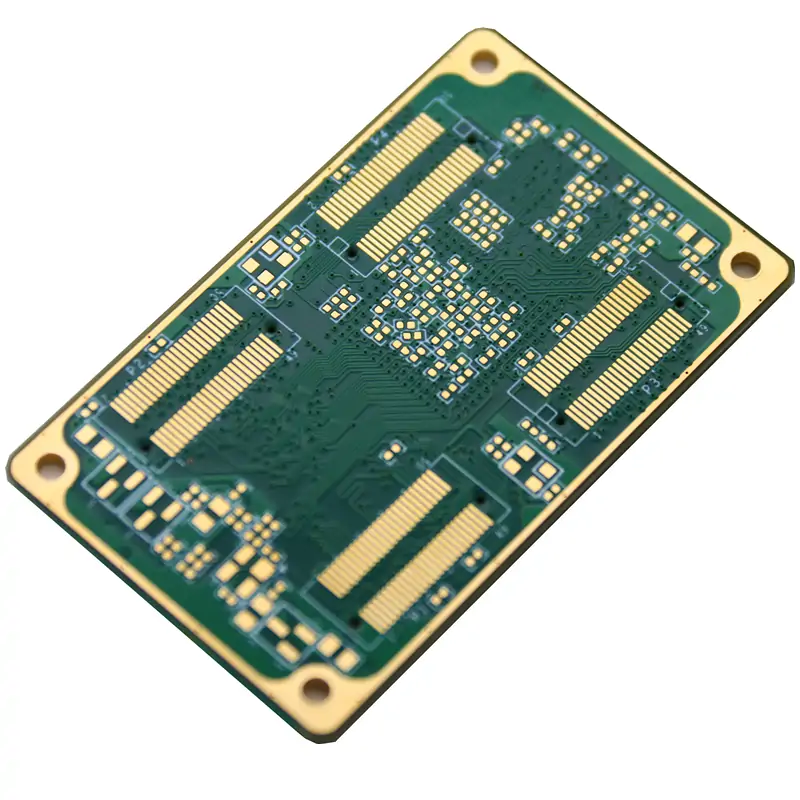

Common specifications for keyboard PCBs include:

Material: FR-4

Surface finish: ENIG or HASL

Solder mask: customizable colors

Consistent PCB fabrication ensures stable electrical performance and visual quality.

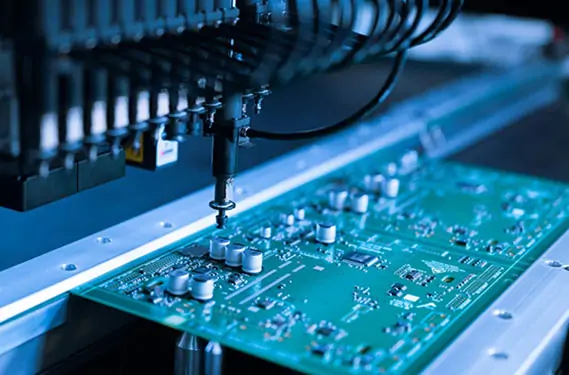

For commercial keyboard projects, PCBA offers:

Higher efficiency

Lower labor cost

Better quality consistency

Hot-swap sockets and SMD components are especially suitable for automated assembly.

Factory-level testing ensures:

Correct key registration

Stable USB communication

No shorts or open circuits

This step minimizes after-sales issues.

Please contact us to experience the difference with high quality of HongRong (shenzhen) Electronics Co.,Ltd.