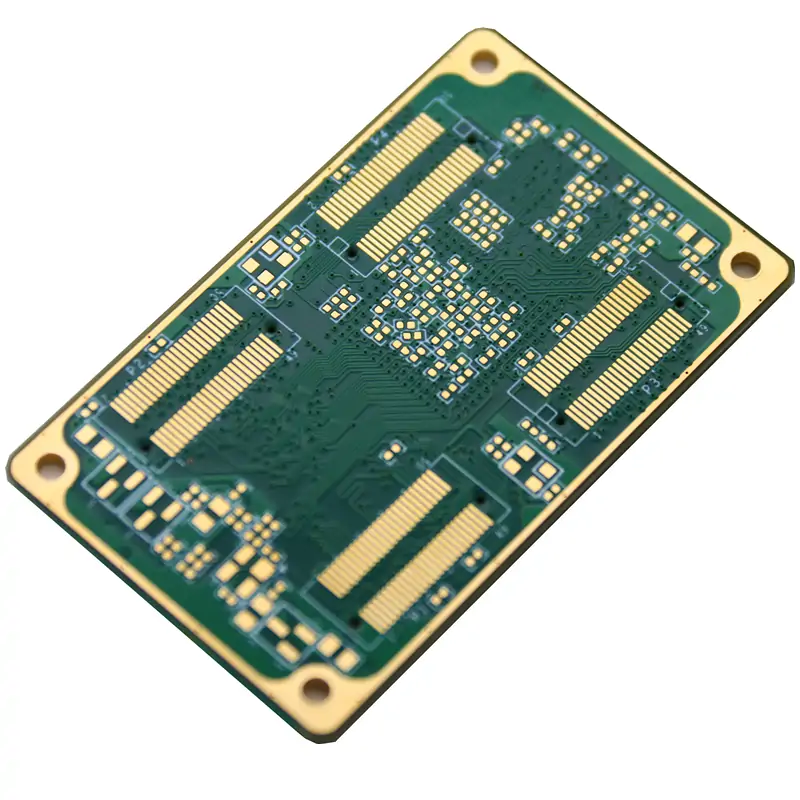

You can see a big difference between through-hole mounting and surface-mount technology. Through-hole mounting needs parts to go through holes in the PCB. Surface-mount technology puts parts right on the board.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hongrong PCBA uses both ways to help you pick the best choice for your electronics project.

There are distinct differences between through-hole mounting and surface mount technology. These two technologies utilize different methods for mounting electronic components to printed circuit boards. In through-hole mounting, component leads are inserted through pre-drilled holes in the PCB and soldered on the other side. In surface mount technology, component leads are placed directly onto pads on the PCB surface and soldered.The table below shows the main differences:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Surface mount technology improves board space utilization and assembly density. Through-hole mounting technology provides a more secure connection between layers. Choosing through-hole mounting technology is particularly important in applications that are subject to external forces or operate in harsh environments.

Why It'sChoosing the right component mounting method is crucial for both project cost and operational performance.If you need a secure bond for powerful devices or military equipment, through-hole mounting is the best option. If you require a small design and high-volume production, surface mount technology can save time and money.

Tip: When you design your PCB, think about what your project needs. Picking the right way helps your product last longer and work better.

Through-hole mounting means you put electronic parts on a printed circuit board by pushing their leads through drilled holes. People use both hands and machines for this job. The steps follow IPC rules and happen in order:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

This way is common when projects need strong and safe connections.

Through-hole mounting gives great mechanical strength. The leads hold parts tightly to the board. This makes the connection last a long time. It works well in places with lots of shaking or heat. You can trust it for things that face strong vibrations or high temperatures. The solder joints help products handle shocks and heat. You see this method in aerospace, cars, and factories where reliability is very important.

Note: Through-hole mounting is good for high power and stress. It works best for parts that deal with big currents and voltages.

Through-hole mounting has its challenges. It requires manual labor, which takes more time. Furthermore, drilling holes requires more material costs. Therefore, this mounting method is not suitable for rapid production of large quantities of products. Furthermore, it can't fit as many components on a circuit board, resulting in limited design flexibility

Through-hole mounting is used in places where things need to be tough and reliable:

Through-hole parts stick to the PCB well, so they are stronger and can handle more stress than surface-mount parts.

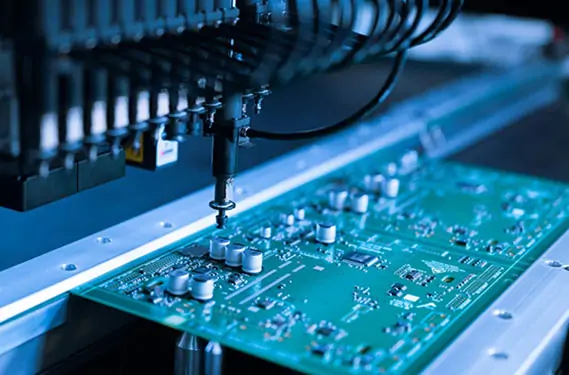

Surface-mount technology lets you put parts right on the board. You do not need to make holes for each part. Machines place and solder the parts very fast. Here is how SMT assembly works:

This way helps you build electronics quickly and accurately.

SMT gives you many good things.

Tip: SMT lets you make lots of good products for less money.

SMT has some problems.

|

|

|

|

|

|

|

|

|

It is also hard to change or upgrade parts, since most SMT parts cannot use sockets.

SMT is used in many places because it helps make lots of products fast.

Today, SMT is used in most electronics. You count on it for quick, strong, and small products.

You should look at the good and bad sides of each way before you pick one. The table below shows how they are different:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Tip: Pick THT if you want strong and lasting parts. Pick SMT if you want to make many boards quickly and cheaply.

There are big changes in price and speed between these two ways. SMT uses machines to put and solder parts, so it is much faster and cheaper for big orders. You can make up to 10,000 boards a day with SMT. THT can only make about 100 to 500 boards a day because people do most of the work.

SMT costs more at first because you need special machines. But you save money on each board when you make a lot. THT is cheaper to start since you just need simple tools. But you pay more for work and supplies for every board. How much you pay for work also depends on how skilled your workers are and how hard your design is.

Note: SMT is better for big projects because it is faster and costs less. THT is better for small projects or test boards if you want to save money at the start.

You should pick the way that fits your project best. Here are some common uses for each:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Remember: Use THT if you need strong and steady parts. Use SMT if you want fast, small, and cheap electronics.

First, think about what your project really needs. Look at how big it should be, how much it can cost, and how strong it must be. Also, decide how many you want to make. Here is a table that shows how the two ways are different:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

If you want to make small things fast with machines, use surface-mount technology. If you need strong parts or big, heavy pieces, use through-hole mounting. Through-hole mounting is better for small amounts. Surface-mount technology is better for making many at once and saves money.

Tip: Pick the way that fits your project’s size, speed, and how strong it needs to be.

Different jobs use different ways to put parts on boards. Here are some real-life examples:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

You see SMT in things like phones and tablets. You find THT in machines for factories and in military gear.

Hongrong PCBA helps you pick the best way for your project. They give advice about design, building, and testing. Their team knows both through-hole and surface-mount technology. You can get help for test boards, big orders, or special needs.

Hongrong PCBA helps you from the start to the end. They make sure your electronics work well and follow the rules.

You want strong connections for parts that face stress or heat. Through-hole mounting gives you reliable performance in tough environments.

Tip: Use through-hole for military or industrial projects.

You can combine both methods on a single board. This approach lets you balance strength and space for your design.

Surface-mount technology saves you money for large production runs. Small batches may cost more because you need special machines.

|

|

|

|

|

|

|

|

|

Please contact us to experience the difference with high quality of HongRong (shenzhen) Electronics Co.,Ltd.