In PCB manufacturing and assembly, cleaning is not a secondary or optional process. It is a core quality-control step that directly affects electrical performance, long-term reliability, and product lifespan. Improper PCB cleaning may not cause immediate failure—but it often leads to latent defects, which are far more costly once products reach the market.

In our previous article, “How to Clean a PCB Without Damaging Components?”, we focused on safe cleaning principles at a general level. In this article, we will explain the right, production-level way to clean a PCB board, and why working with a professional PCB & PCBA manufacturer makes a measurable difference.

Many electronic failures are not caused by poor design, but by process-related contamination left on the PCB after assembly.

Flux residues, ionic contaminants, and trapped moisture can slowly degrade circuit performance. Over time, this may result in:

Electrical leakage paths forming between conductors

Reduced insulation resistance

Signal distortion in high-speed or RF circuits

Corrosion under fine-pitch components such as BGA and QFN

These issues often appear weeks or months after deployment, especially in humid or high-temperature environments—making them difficult to trace back to the root cause.

During PCB fabrication and PCBA processes, contamination can occur at multiple stages.

Common sources include

Flux residues generated during soldering and reflow

Dust and micro-particles from the production environment

Fingerprints and oils introduced during handling or inspection

Ionic residues from materials, chemicals, or water

Moisture trapped beneath components or in vias

Different contamination types require different cleaning strategies. Treating all PCBs the same often leads to incomplete cleaning or hidden reliability risks.

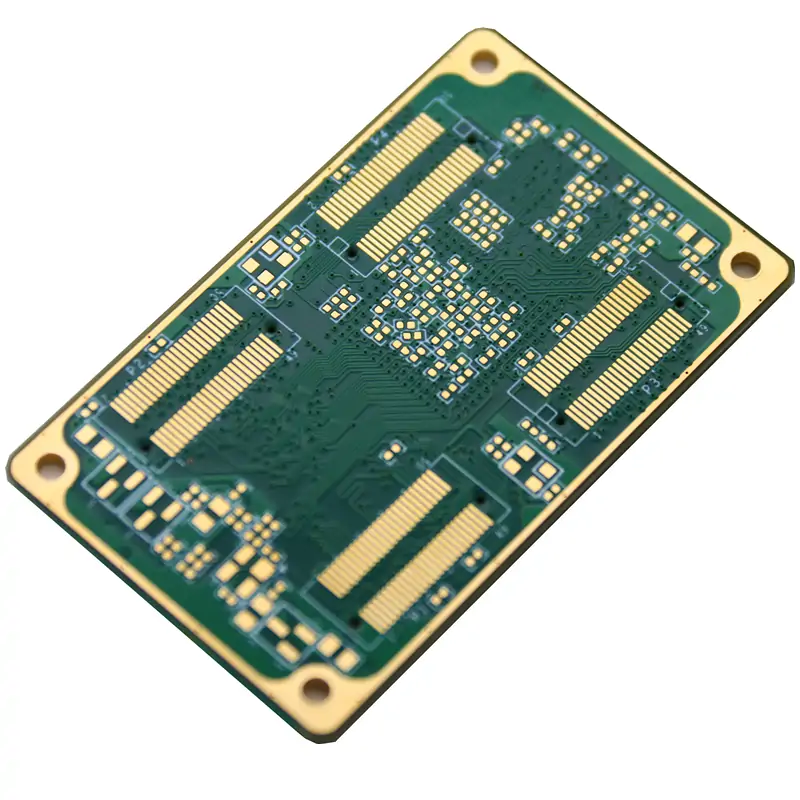

Professional PCB cleaning always starts with understanding the board itself.

Key factors include:

Component density and package types

Soldering process and flux formulation

Operating voltage and signal frequency

End-use environment (industrial, medical, automotive, etc.)

For example, a high-frequency PCB or industrial control board requires a much stricter cleanliness level than a basic consumer product.

IPA cleaning is commonly used for prototypes, repairs, and low-volume production.

90%–99% IPA effectively dissolves most flux residues

Safe for most electronic components when applied correctly

Ideal for manual rework and small-batch PCBA

However, IPA cleaning relies heavily on operator skill and consistency.

DI water cleaning is widely used in professional PCBA factories.

Especially effective for water-soluble flux

Provides uniform cleaning across complex assemblies

Requires controlled drying to avoid moisture-related defects

This method is suitable for OEM and ODM projects with stable production volumes.

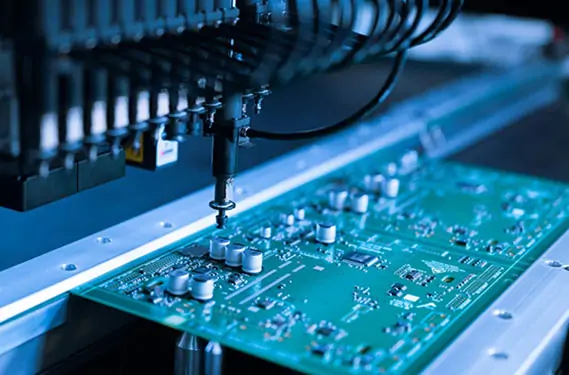

For high-density, high-reliability, or mass-production PCBs, automated cleaning systems are preferred.

Compatible with ultrasonic and inline cleaning equipment

Ensures repeatable and consistent cleanliness

Reduces human error and process variability

This approach is commonly used in EMS projects and long-term production programs.

Cleaning alone is not enough—drying is equally critical.

Moisture left under components can cause:

Corrosion over time

Electrical leakage

Reduced dielectric strength

Professional PCBA manufacturers use:

Low-temperature baking

Clean, oil-free compressed air

Process inspections to verify cleanliness and dryness

This ensures the PCB is fully ready for testing, assembly, or shipment.

| Cleaning Method | Typical Use | Reliability Risk |

|---|---|---|

| Manual Cleaning | Prototypes, rework | Medium |

| Semi-Automated Cleaning | OEM / ODM batches | Low |

| Fully Automated Cleaning | EMS mass production | Very Low |

For commercial products, factory-level PCB cleaning significantly reduces long-term failure risk and improves consistency.

When PCB fabrication, assembly, and cleaning are handled by different suppliers, process gaps often appear.

At HongRong (Shenzhen) Electronics Co., Ltd., PCB cleaning is fully integrated into our one-stop PCB manufacturing and assembly services.Our capabilities include:

PCB fabrication

PCB assembly (PCBA)

Turnkey and one-stop solutions

OEM, ODM, and EMS services

By managing the entire process in-house, we ensure that PCB cleanliness, assembly quality, and final reliability are aligned from the start.

Choosing a professional PCBA partner means more than just manufacturing capacity.

You benefit from:

Fewer post-shipment failures

Reduced rework and warranty costs

Improved product reliability and consistency

Faster project execution and time-to-market

As emphasized in How to Clean a PCB Without Damaging Components?

, safe cleaning is essential—but process control and experience are what ensure long-term success.

If your project requires:

Stable and consistent PCB manufacturing

Professional PCB assembly

One-stop, turnkey, OEM, ODM, or EMS services

HongRong (Shenzhen) Electronics Co., Ltd. is ready to support your project with proven manufacturing processes and quality-focused execution.

⇒Contact us today to discuss your PCB or PCBA requirements and receive a fast, professional quotation.

Not every PCB requires the same level of cleaning, but in most professional PCB assembly projects, cleaning is strongly recommended.

PCBs used in industrial, automotive, medical, or high-frequency applications are especially sensitive to flux residues and ionic contamination. Even “no-clean” flux can leave residues that affect long-term reliability.

An experienced PCBA manufacturer will evaluate whether cleaning is required based on design, application, and reliability standards.

Unremoved flux residue may lead to:

Electrical leakage paths

Reduced insulation resistance

Corrosion under components

Signal instability over time

These issues often appear after the product is in the field, making troubleshooting difficult and costly. Proper PCB cleaning during assembly significantly reduces these risks.

Yes. Using incorrect solvents, excessive force, or uncontrolled drying can damage components, solder joints, or PCB surfaces.

As discussed in our previous article “How to Clean a PCB Without Damaging Components?”, professional PCB cleaning requires:

Correct cleaning agents

ESD-safe tools

Controlled processes

This is why factory-level cleaning is safer than ad-hoc manual cleaning.

There is no single “best” method—it depends on:

Flux type

Component density

Production volume

End-use environment

For OEM and ODM projects, professional PCBA factories often use DI water or automated cleaning systems to ensure consistency, repeatability, and compliance with quality standards.

Moisture control is a critical part of the cleaning process.

Professional PCBA manufacturers use:

Low-temperature baking

Oil-free compressed air

Controlled drying environments

These measures prevent moisture from being trapped under components such as BGA or QFN packages.

Manual cleaning can be acceptable for prototypes or small rework tasks, but it is not recommended for mass production.

For EMS and volume production, automated or semi-automated PCB cleaning provides:

Consistent results

Lower defect risk

Better long-term reliabil

Yes. High-frequency and RF PCBs are particularly sensitive to contamination.

Flux residues and ionic pollution can:

Alter impedance

Increase signal loss

Introduce noise

This makes professional PCB cleaning especially important for communication, RF, and high-speed digital applications.

Absolutely. PCB cleaning should be a standard part of a turnkey or one-stop PCBA solution.

When fabrication, assembly, cleaning, and testing are handled by a single supplier, process consistency improves and quality risks are reduced.

Buyers should ask:

What cleaning methods are used?

How is drying controlled and verified?

Is cleaning integrated into the assembly process?

Does the supplier support OEM, ODM, and EMS projects?

An experienced PCBA manufacturer can clearly explain their cleaning and quality-control procedures.

Yes. HongRong (Shenzhen) Electronics Co., Ltd. provides one-stop PCB manufacturing and assembly services, where PCB cleaning is fully integrated into the production process.

We support:

PCB fabrication

PCB assembly (PCBA)

Turnkey & one-stop solutions

OEM, ODM, and EMS projects

This ensures your PCBs are not only manufactured and assembled—but also cleaned, inspected, and delivered to professional standards.

Please contact us to experience the difference with high quality of HongRong (shenzhen) Electronics Co.,Ltd.