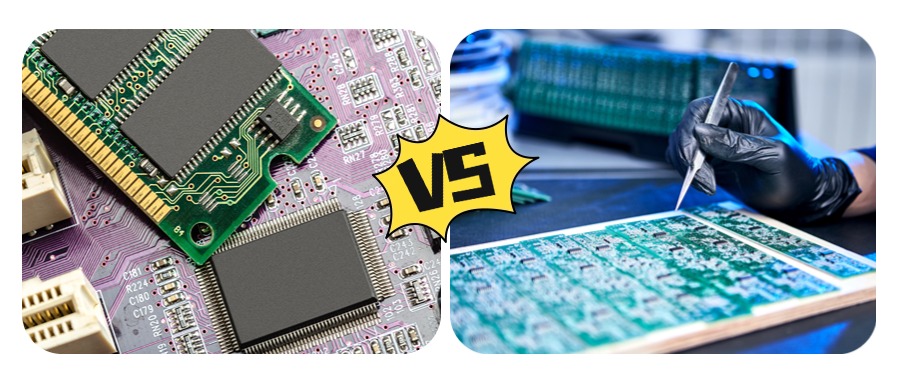

Here is a table that shows how the two compare in real-world use:

|

Aspect |

PCB (Printed Circuit Board) |

PCBA (Printed Circuit Board Assembly) |

|---|---|---|

|

Functional Role |

Bare board, only supports and connects parts |

Fully assembled, performs electronic functions |

|

Cost |

Low, just a few dollars for simple boards |

Higher, includes parts, labor, and testing |

|

Manufacturing Process |

Only board fabrication |

Adds soldering, assembly, and more steps |

|

Testing |

Basic checks for board quality |

Full testing for function and reliability |

|

Application Contexts |

Prototyping, DIY, base for assembly |

Used in finished products like phones, cars, and medical devices |

|

Example Industries |

Education, startups |

Consumer electronics, automotive, medical, industrial, telecom, aerospace |

|

Performance Impact |

No active function, just pathways |

Runs the device, handles complex tasks, meets strict standards |

You can see that only the PCBA can make your device work. Quality assurance for PCBA includes many steps, such as solder paste inspection, automated optical inspection, and reflow soldering checks. These steps make sure every part is in the right place and works as it should. Bare PCBs do not need these tests because they do not have any parts yet.

Testing for PCBAs is much more detailed. You will find methods like in-circuit testing, flying probe testing, and even X-ray inspection. These tests check that every part is connected and working. Burn-in testing puts the PCBA under stress to catch early failures. These steps are not needed for a bare PCB.

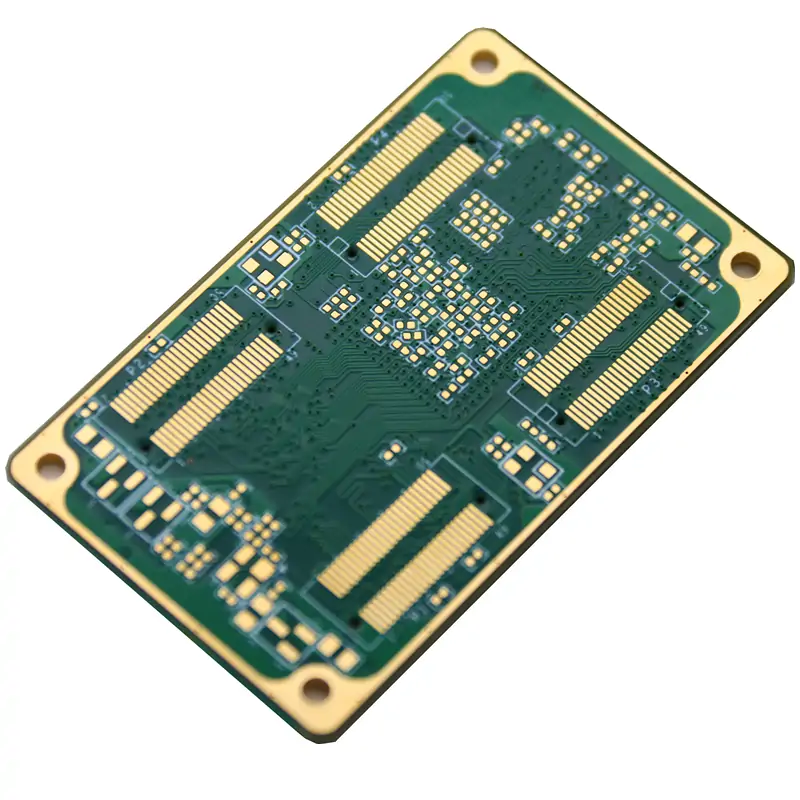

The cost of making a circuit board is determined by the number of layers, board material, process complexity, and order quantity of the PCB. Generally, multi-layer boards and special processes (such as blind holes and immersion gold) have high costs. The larger the order batch, the lower the unit price of the PCB.

Building a PCBA costs more and takes more work. You must buy all the parts, pay for assembly, and run many tests. The process uses advanced machines for placing parts and soldering. You also need skilled workers and good supply chain management.

Here are some reasons why PCBA is more complex and expensive:

Complex designs and multi-layer boards take more time and skill.

Special or high-performance parts cost more.

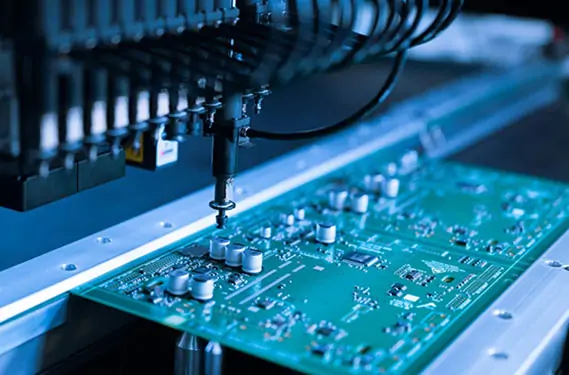

Surface mount technology uses automated machines, which need a big upfront investment.

Extra testing and quality checks add to the cost.

Automation helps, but you must invest in equipment and training.

Larger or thicker boards need more materials and longer production times.

Making many units lowers the cost per board, but the first batch is always more expensive.

Automation can lower labor costs, but you must spend more on machines.

Data analytics and quality control make the process better, but also add to the complexity.

| Remember: A PCB is cheap and simple, but only a PCBA gives you a working product. You must plan for the extra steps, cost, and testing if you want a reliable device

Project Needs

You should start by looking at your project’s goals. Think about what you want your device to do and how complex it needs to be. If you only need a simple circuit, a bare PCB might be enough. For more advanced projects, you will likely need a fully assembled board. Design for Manufacturability (DFM) analysis can help you spot problems early and save money. By using DFM, you can avoid extra trial runs and reduce repair costs. Studies show that DFM can save up to $170,000 each year by making the design and manufacturing process smoother. However, you need skilled partners to get the most out of this approach.

| PCB boards are the core foundation of high-tech industries. As manufacturing technology continues to evolve, PCBs are also evolving towards high density, high frequency and speed, flexibility and high reliability. You should choose according to the needs of your project.

A bare PCB works well for simple or early-stage projects. You might use it for prototyping, educational kits, or basic DIY electronics. Here are some best practices based on industry case studies:

1. Choose components with a safety margin. Experts recommend using parts at 70-80% of their rated values for better reliability.

2. Make sure your parts can handle the right temperature range. For example, automotive projects need parts rated from -40°C to 125°C.

3. Plan for part shortages by picking alternatives ahead of time. This can cut redesign time by more than half.

4. Optimize your component choices to lower costs without losing performance.

5. Check manufacturer data for reliability to reduce failures.

6. Pick parts that fit well with your assembly process to avoid defects.

7. Follow rules for environmental safety, like RoHS and REACH.

A PCB is a good choice when you want to control the assembly yourself or when your design is still changing.

You should choose a pcba when you need a ready-to-use, reliable solution. This is important for products that must work right out of the box, such as consumer electronics, cars, or medical devices. In the automotive industry, for example, assembled boards connect and control key systems like engines, brakes, and safety features. High-quality assembly ensures these systems work safely and last longer. New trends, like high-frequency boards for radar and advanced coatings, make pcba even more reliable in tough environments. Modular designs and smart factories also help improve quality and make repairs easier.

If your project needs high performance, strong reliability, or must meet strict industry standards, a pcba is the best choice.

You now know that a PCB gives you the basic structure for your circuit, while a PCBA delivers a complete, working board. PCBs focus on design flexibility and serve as the foundation for your project. PCBAs add all the electronic parts, making your device reliable and ready to use.

PCBs work best for early designs and simple projects.

PCBAs fit finished products in industries like automotive, medical, and consumer electronics.

Choose the right option to match your project’s needs and improve your results.

PCB stands for Printed Circuit Board. You use it as the base for building electronic circuits. It has copper traces that connect different parts.

You cannot use a PCB alone. It does not have any electronic parts. You need to add components to make it work.

PCBA costs more because you pay for the board, all the electronic parts, assembly, and testing. You get a ready-to-use product.

You should look at your project needs. If you want to build and test your own circuit, start with a PCB. If you need a working board right away, choose a PCBA.

Please contact us to experience the difference with high quality of HongRong (shenzhen) Electronics Co.,Ltd.