Looking closely helps find problems like misalignment and bad soldering early. This saves time and money.

High-tech tools like AOI and X-ray testing find hidden PCBA issues better.ICT checks if parts are in the right place and working. It stops problems from getting worse.

Functional testing copies real-life use to check performance. This makes sure the PCBA works as planned.

Compliance testing ensures products follow rules, lowers risks, and gains customer trust.

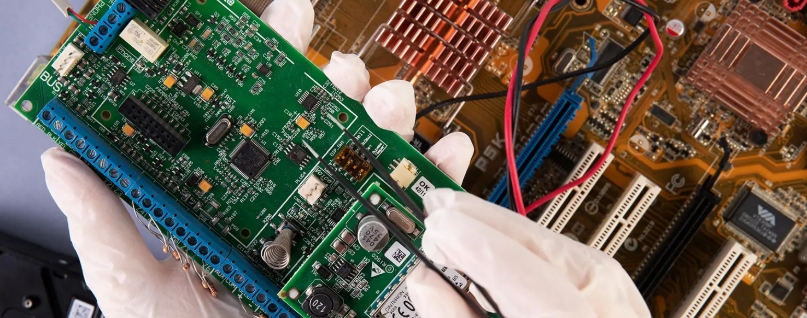

Looking closely at your PCBA is very important. It helps find visible problems early, saving time and money. You can spot things like parts not lined up, bad soldering, or broken pieces. This step makes sure your product works well and matches the design.

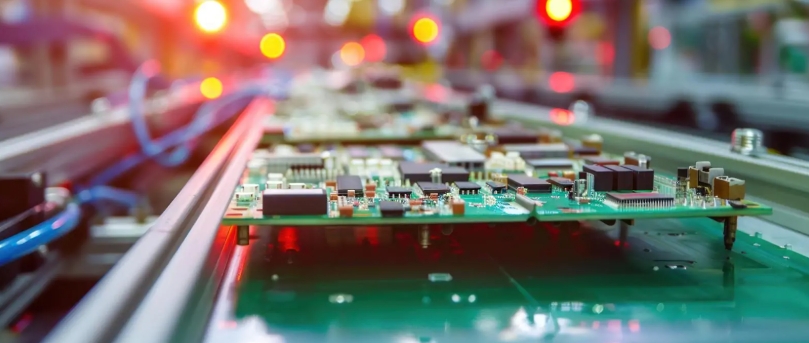

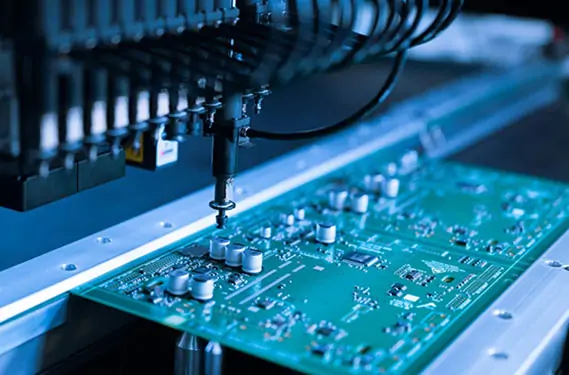

New tools make checking PCBA easier and better. Automated Optical Inspection (AOI) takes clear pictures to check part placement. AOI gives quick results so you can fix mistakes fast.

For hidden parts, Automated X-Ray Inspection (AXI) is needed. AXI uses X-rays to find soldering problems AOI can’t see. These tools are fast and accurate, helping keep quality high.

When inspecting, you might find these common problems:

Soldering Problems: Weak joints, solder bridges, or too little solder can cause issues.

Component Misalignment: Parts in the wrong spot or facing the wrong way can stop it from working.

Physical Damage: Cracks, scratches, or broken parts make the assembly weaker.

Fixing these problems early makes your product more reliable and reduces defects later.

Thermal imaging helps find problems in your PCBA. It uses heat patterns to show issues in parts or solder joints. If a part overheats or doesn’t handle heat well, this method spots it fast. Fixing these problems early stops bigger issues later.

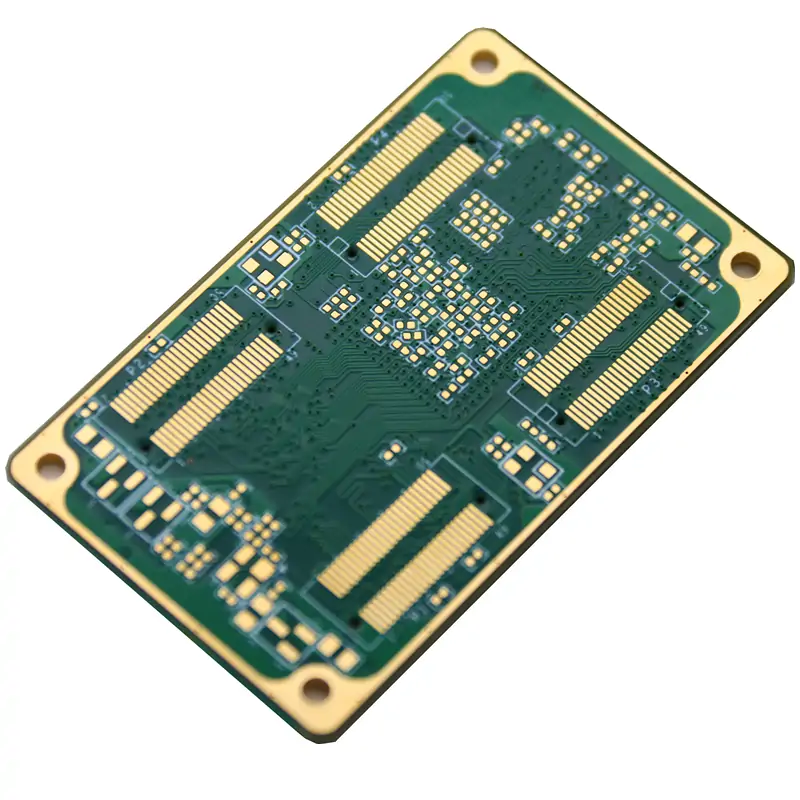

X-ray testing finds hidden problems in multi-layer PCBs. It looks inside the layers to spot issues you can’t see. This method is great for finding solder problems like cracks or gaps.

Unlike older methods, X-rays give a clear view inside. They help find problems in hard-to-see parts like ball grid arrays (BGAs). Adding X-ray testing ensures your PCBA is high quality.

In-Circuit Testing (ICT) is a trusted way to check PCBA. It tests if parts work and are connected right. ICT measures things like voltage, current, and resistance to confirm everything is okay.

ICT has many benefits:

It finds problems early in assembly.

It checks if parts are placed and soldered correctly.

It ensures the design matches the plan.

ICT catches problems before they ruin the product. This saves time and money on fixing mistakes. Tools like multimeters make ICT even better by giving exact readings.

Functional testing checks if your PCBA works as it should. It tests how well the assembly performs its job, making it a key step.

Functional testing copies the real-world use of your PCBA. You connect it to a system that acts like its actual application. This test checks if the board reacts right to inputs and gives correct outputs. For example, if your PCBA runs a motor, the test ensures it starts, stops, and changes speed properly.

Functional testing has many benefits:

Comprehensive Validation: It checks all parts, connections, and software together.

Real-World Assurance: Testing in real-like conditions ensures it works in its final use.

Early Problem Detection: It finds issues like bad programming or broken parts early.

Functional testing uses special tools made for your PCBA. Common tools include:

Test Jigs: Hold the PCBA and link it to the test system.

Automated Test Equipment (ATE): Speeds up testing and makes it more accurate.

Software Simulators: Mimic the PCBA's real-world use to check its functions.

Follow these tips for better results:

Define Clear Test Parameters: Set clear rules for inputs, outputs, and performance.

Use Reliable Equipment: Make sure your tools work and are well-calibrated.

Test in Stages: Start simple, then test more complex tasks step by step.

Repeat Tests: Test multiple times to ensure it works consistently.

Functional testing is the last check before using your PCBA. Careful testing ensures your product works well and reliably.

Solderability testing checks if solder joints are strong and reliable. Weak solder joints can cause electrical or mechanical problems. This test shows how well solder sticks to parts and the board.

You can use tests like the wetting balance test or dip-and-look test. The wetting balance test measures how solder spreads on a surface. The dip-and-look test dips parts into melted solder and checks them. These tests find problems like dirt or rust that stop good soldering.

Mechanical stress testing checks if your PCBA can handle physical forces. It copies real-life situations like shaking, dropping, or bending. This ensures the assembly stays strong during shipping or use.

Tools like vibration tables and drop testers help with this test. A vibration table shakes the PCBA to mimic transport. A drop tester checks how it handles sudden falls. These tests find weak spots so you can fix them.

Durability testing checks how your PCBA performs over time. It tests against heat, moisture, and repeated stress. This helps predict how long your product will last.

Environmental chambers create tough conditions for testing. For example, thermal cycling switches between hot and cold to find material problems. Fixing issues early makes your product last longer.

Compliance testing checks if your PCBA follows industry rules. These rules ensure electronic assemblies are safe, reliable, and high-quality. Meeting them is necessary to sell products and gain customer trust.

Some important standards include:

IPC-A-600: Explains what makes a PCB acceptable and high-quality.

PDA/ANSI Standard 06-2025: Focuses on building strong teams and excellent work habits.

The Consumer Electronics Association says following these rules lowers product failures by 30%. Compliance testing also prevents expensive recalls and ensures your product works well in real use.

Compliance testing uses specific steps to check if your PCBA meets rules. First, find out which standards apply to your product. Then, test how it performs in different situations.

Main steps include:

Visual Checks: Look for problems like crooked parts or bad soldering.

Electrical Tests: Check voltage, current, and resistance to confirm it works.

Environmental Tests: Test how it handles heat, moisture, and shaking.

Tools like automated test equipment (ATE) make testing faster and more accurate. Write down all results to track progress and find areas to improve.

Following compliance rules has many benefits. It makes sure your PCBA is safe, works well, and is ready to sell. It also helps customers trust your brand and builds a good reputation.

Other benefits include:

Lower Risks: Testing reduces the chance of failures or recalls.

Easier Market Entry: Products meeting standards like IPC-A-600 can sell worldwide.

Better Quality: Following rules improves how products are made and how they perform.

Focusing on compliance testing helps you create reliable products that succeed in competitive markets.

Testing your PCBA needs different methods like visual and electrical checks. Advanced and compliance tests are also important for finding issues. Each method helps ensure quality and spot problems early. Following a clear testing process makes products last longer and work better. Using good practices reduces mistakes and boosts performance. This helps your assemblies meet customer needs and compete well in the market.

Automated Optical Inspection (AOI) is the top choice. It takes clear pictures to find problems like crooked parts or bad soldering. AOI gives fast and accurate results, keeping quality high.

X-ray testing finds hidden problems in layered PCBs. It spots cracks or gaps in solder and shows inside details. This method is great for checking complex designs and ensuring reliability.

Functional testing checks if your PCBA does its job. It copies real-world use to test inputs, outputs, and how it works overall. This step makes sure your product works well before being used.

Important rules include IPC-A-600 for PCB quality and ANSI/PDA Standard 06-2025 for good manufacturing. Following these rules keeps your assembly safe and reliable. It also lowers risks and builds trust with customers.

Use tests like the wetting balance test to check solder stickiness. Clean parts and boards before soldering to stop dirt problems. Regular checks and care keep joints strong and lasting longer.

Please contact us to experience the difference with high quality of HongRong (shenzhen) Electronics Co.,Ltd.